Prestressed Concrete Strand

WE PRODUCE PRODUCTS THAT SHAPE THE FUTURE OF CONSTRUCTION

Primary Advantages

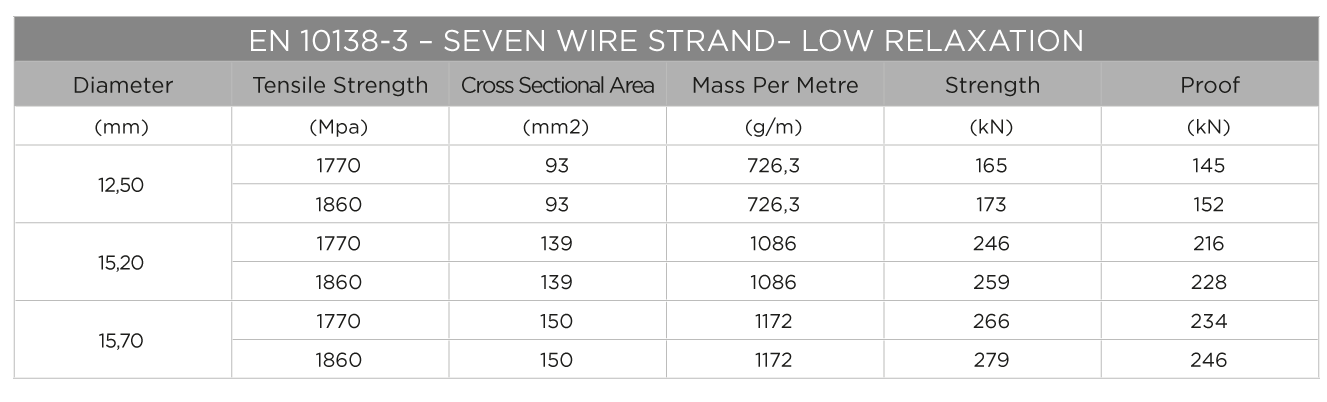

PC strand with 7 strands that are used in the areas such as bridge girder production, prefabricated construction elements, ground and mine anchorages, nuclear power stations, silo constructions, housing constructions are produced according to the ASTM, BS, EN and TSE standards.

What is Prestressing?

Prestressing is to apply constant stress artificially to structural components before applying external loads. For the prestressing concrete wires and strands in various dimensions, types and resistances, which are produced exclusively, are used Prestressing concrete steel elements are produced by taking stress from high carbon special wire rods with vanadium alloys after a distinct load and a regular patenting treatment.

Designing of prestressed concrete structures

In prestressed concrete structures the prestressing applied initially is decreasing in time due to warping and creep of concrete and relaxation of prestressing steels. Therefore, the characteristics of the steel defined as steel relaxation under constant length or loss of stress is one of the important parameters taking into consideration in designing of prestressed concrete structures.

Advantages of the products with lower relaxation:

- More tensile and yield strenghts.

- Super durability against fatigue and corrosion.

- Consistent load elongation relation.

- Super straightening feature.

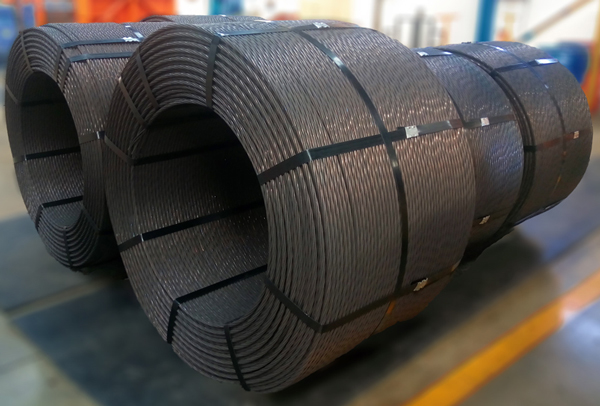

Measures for Storage

Some of the measures have to be taken during the use of prestressing concrete steel :

- Prestressing concrete steel is sensitive against intensive heat sources.

- Internal structure and mechanical features of steel may be changed if it is exposed to intensive heating.

- Loading and discharging have to be made in minimum amounts and corrosion and pressure have to be avoided in order not to change mechanical features.

- Coils have to be stowed over ground level and they have to be covered in a way that they allow a good air circulation in order to avoid condensation.