Elevator Ropes

General Characteristics of Elevator Ropes

The ropes are elastic and with thick external wires. Resistance to Abrasion conditions are good. Choosing ropes in elevators carrying humans with at least 12 safety coefficient is advisable. Minimum breaking resistance may be 140,160 or 180 kg/mm2. Wires having two strength characteristics may be used in special elevator ropes. Ropes must be lubricated. They must be checked up frequently in use and controls made be recorded.

For the Elevator Ropes following points are important;

- Resistance to fatigue,

- Resistance to abrasion,

- Lack of nerve,

- Appropriate preform characteristics.

Elevator Ropes

CelikLift 819+ - 8x19 S PRE-STRECHED ELEVATOR WIRE ROPES

Diameter Range: 8-14(mm)

Number Of Wires: 152

Average Fill Factor: 0,444

Average Spin Factor: 0,839

Number Of Wires: 152

Average Fill Factor: 0,444

Average Spin Factor: 0,839

CelikLift 819+ IWRC - 8x19 S PRE-STRECHED ELEVATOR WIRE ROPES

Diameter Range: 8-14(mm)

Number Of Wires: 201

Average Fill Factor: 0,581

Average Spin Factor: 0,779

Number Of Wires: 201

Average Fill Factor: 0,581

Average Spin Factor: 0,779

CelikRope 619 FC - 6x19 S FC WIRE ROPES

Diameter Range: 8-57(mm)

Number Of Wires: 114

Average Fill Factor: 0488

Average Spin Factor: 0,859

Number Of Wires: 114

Average Fill Factor: 0488

Average Spin Factor: 0,859

CelikRope 819 FC - 8x19 S FC WIRE ROPES

Diameter Range: 8-68(mm)

Number of Wires: 152

Average Fill Factor: 0,444

Average Spin Factor: 0,839

Number of Wires: 152

Average Fill Factor: 0,444

Average Spin Factor: 0,839

CelikRope 819 IWRC - 8x19 S IWRC WIRE ROPES

Diameter Range: 8-68(mm)

Number of Wires: 201

Average Fill Factor: 0,581

Average Spin Factor: 0,779

Number of Wires: 201

Average Fill Factor: 0,581

Average Spin Factor: 0,779

CelikRope 819 W FC - 8x19 W FC WIRE ROPES

Diameter Range: 8-83(mm)

Number of Wires: 152

Average Fill Factor: 0,444

Average Spin Factor: 0,839

Number of Wires: 152

Average Fill Factor: 0,444

Average Spin Factor: 0,839

CelikRope 819 W IWRC - 8x19 W IWRC WIRE ROPES

Diameter Range: 8-83(mm)

Number of Wires: 201

Average Fill Factor: 0,581

Average Spin Factor: 0,779

Number of Wires: 201

Average Fill Factor: 0,581

Average Spin Factor: 0,779

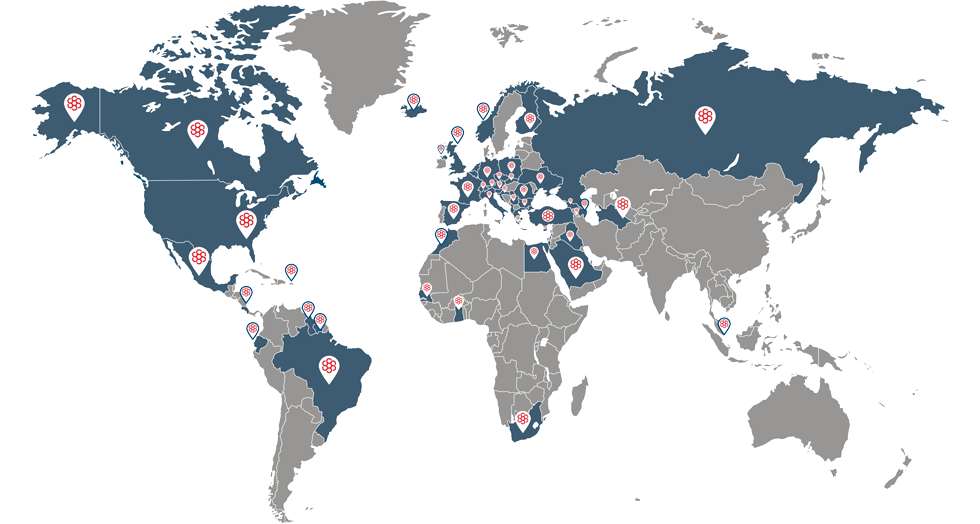

Product Finder

One step to reach technical specifications or additional details of product.

One step to reach technical specifications or additional details of product.